Three Wageningen research projects recently got funding from an American research fund. Wageningen is a leading light in shear cell technology, but large-scale applications are still in the future.

© Niels Blekemolen

Last year, Wageningen researchers submitted three project proposals to The Good Food Institute (GFI), an American non-profit organization that pumps funding from philanthropists into the development of meat substitutes. This fund had not previously financed research in the Netherlands, but at the end of March, all three of the Wageningen researchers received a grant of between 150,000 and 250,000 dollars. ‘The Americans are interested in Wageningen’s research and in the shear cell technology,’ says Miek Schlangen, who is just embarking on her PhD research. She wrote her own PhD proposal and can now carry it out with funding from GFI, supervised by Atze Jan van der Goot from the Food Process Engineering chair group.

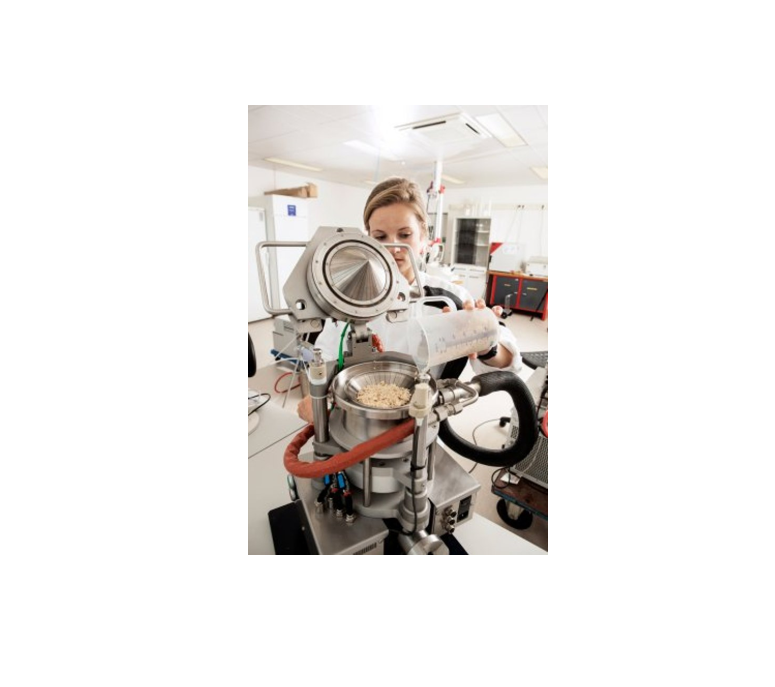

The shear cell technique that Van der Goot developed in 2010 is a process that shreds (or shears) plant proteins until they are reduced to fibrous structures whose appearance and texture come very close to those of meat. Plant proteins from soya go into a machine (the shear cell) in which they are heated to between 100 and 140 degrees Celsius. As the mixture is shredded in the machine, the proteins end up all in one line, creating a fibrous structure.

Since then, the researchers have found out how to control the tenderness and texture of the artificial meat, depending on the ingredients, the temperature and the pressure in the machine. They can for instance make a 100-gram vegetarian beefsteak using the shear cell technology, and seven-kilo cuts of ‘meat’ using a scaled-up version of the machine.

There still isn’t a company marketing large slices of meat substitute

Peas and mung beans

In her PhD research, Schlangen is going to look at whether she can expand the number of ingredients used in the meat substitutes. Up to now, most of them are made of a protein isolate from soya. Schlangen wants to start using peas and mung beans as well, and to look at how mixtures of proteins and other components they contain behave in the shear cell. She wants to find out how best to fractionate the proteins from these pulses to obtain the right structure for a meat substitute. Her goal is to make several, more sustainable sources of protein available for the meat substitutes.

Another of the grants from the American organization GFI went to a former PhD student of Atze Jan van de Goot’s, Birgit Dekkers. Dekkers is now the founder and director of Rival Foods, a Wageningen spin-off with a staff of six which aims to market shear cell technology. Dekkers wants to scale up the production process by developing the world’s first compact, easy-to-use shear cell machine. And Rival Foods also wants to expand the range of meat substitutes on offer.

Fish, chicken and red meat

Currently, most meat substitutes are hamburgers and sausages – processed artificial meat. Dekkers wants to make high-end culinary products. So she is going to use the American grant to find out how she can imitate three product categories using the shear cell technology: Rival At Sea, a layered product resembling fish; Rival On Land, a heterogeneous fibrous structure resembling red meat; and Rival With Wings, a more homogeneous, finer, soft fibrous structure resembling poultry.

The spin-off is only six months old and is not yet producing meat substitutes. The GFI grant should enable the company to set up a production unit for vegetarian beef slices. ‘There still isn’t a company that is marketing meat substitutes in large slices,’ says Miek Schlangen. ‘That would be of interest to butchers and chefs, for instance. They can then really slice a vegetarian beefsteak off a 10-kilo block.’

Rival Foods hopes to learn from Schlangen’s research too. Dekkers: ‘We are looking for alternative sources of protein with which to make meat substitutes. I am very curious to see whether we can soon produce meat and fish substitutes made out of mung beans as well.’

I want to make meat substitutes out of stalks and leaves that now end up on the compost heap

Organic waste

Marieke Bruins of WUR’s Food & Biobased Research wants to go a step further. ‘You can make meat substitutes out of soya and peas, but you can also eat those food directly. I want to make meat substitutes out of agricultural waste streams: the stalks and leaves of plants that now end up on the compost heap.’ Her project won funding from The Good Food Initiative too.

Bruins is going to study whether the proteins from plant waste – from tomato and cucumber plants, for instance, can be used to make meat substitutes. Leaves contain the protein rubisco, which she suspects could be given a very nice meaty structure with a good bite to it, using shear cell technology. ‘I’m going to figure out whether the proteins are suitable for use in meat substitute products.’

Bruins wants to know how she can extract the proteins from the waste streams and how she can purify the various protein fractions. Bruins is doing this research together with Elke Scholten of the Physics and Physical Chemistry chair group.

Centre for meat substitutes

With the grants from The Good Food Company, WUR hopes to maintain its frontrunner position in research on meat substitutes, says personal professor Atze Jan van der Goot. ‘We were quick off the mark in Wageningen with research on alternative proteins.’ Van der Goot points to the research programme Profetas (Protein Foods, Environment, Technology and Society), in which Wageningen researchers were working on meat substitutes as far back as 2004.

In the same period, researchers at Food & Biobased Research developed new meat substitutes with the help of extruders: a kind of mill that mixes, grinds, and sticks together the proteins. This lead to the Wageningen spin-off Ojah BV, which has been produced vegetarian chicken chunks using extruders on a large scale since 2009. Many meat substitutes are now made using extruders.

Van der Goot developed the shear cell technology with a view to making other kinds of plant-based meat as well. At the moment, six Wageningen PhD students are working on meat substitutes. The professor wants to use the knowledge generated by the new projects to make the extruder technology more efficient and sustainable. ‘We still have a headstart in Wageningen. WUR is the centre for meat substitutes and I want to keep it that way.’