PhD student Johannes Kuipers, who graduates tomorrow in Leeuwarden, thought up an ingenious system using wireless LED lighting to break down the remains of these drugs.

The process Kuipers applies is called photocatalysis: breakdown under the influence of light. The pollution is broken down by light on the surface of small balls of titanium oxide, the catalyst in this process. Through the catalyst, the light creates highly reactive radicals which attack the pollution. Photocatalysis is not new in itself, but the way Kuipers illuminates the contents of the reactor certainly is.

The illumination of the titanium oxide is an essential part of the process. Various ways of doing this have been developed, all making use of fixed lamps. ‘The problem with that is the permeability of the light,’ explains Kuipers. ‘In waste water with a suspension of titanium oxide, light only penetrates a couple of millimetres. The challenge is to light up the largest possible surface area of titanium oxide. Our idea is to do that with floating LED lamps.’

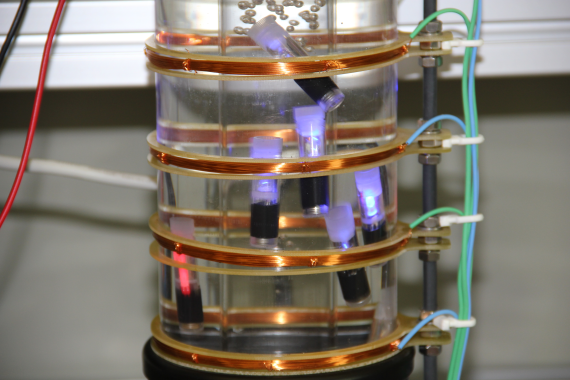

A spectacular idea in itself, but even more impressive is the fact that it is all wireless. Rather than running on batteries, the little LED lamps get their electricity delivered wirelessly, floating around in the reactor as if by magic. The technique ‘magician’ Kuipers uses to achieve this is called resonant induction coupling.

The transformer is based in the principle of induction: electricity passing from one coil to the other. Kuipers uses the reactor tank, which is wrapped in electric cable, as one big coil. The LED lamps in the tank are the small coils on the receiving end. By getting the two to resonate with each other, energy is transferred efficiently and wirelessly. The LED lights are small cubes of a couple of cubic millimetres.

The principle works. Kuipers used it to rid waste water from a membrane bioreactor of a mixture of seven commonly used drugs which are difficult to remove. The free-floating LED lamps do the work one and a half times faster that fixed LED lamps, and use 35 percent less energy. The system is still too expensive as yet, though. But that could soon change, says Kuipers.

LED technology is developing fast. LEDS are getting smaller and cheaper. This makes illuminating the catalyst, which is the real motor of the purification, more efficient. There is quite some scope for increasing the efficiency of the catalyst itself, according to Kuipers. At the moment only five percent of the light is used for oxidation. ‘If you can make that 50 percent you will have a big improvement.’