Young soldiers get personalized snacks from a 3D printer and eat them in the woods in Brabant province. Resource editor Dominique Vrouwenvelder went along with WUR researcher Martijn Noort.

There’s a container outside the office of the Netherlands Organization for Applied Scientific Research (TNO) on the High Tech Campus in Eindhoven. This cabin is a mini food factory producing personalized snacks for soldiers. The snacks are not made by chefs but by a 3D printer. WUR is part of the research consortium IMAGINE (see inset), which is developing the technology for making on-demand personalized food products.

By the time WUR researcher Martijn Noort and I arrive at the container — or Military Mobile Satellite Kitchen, to use its official ministry of Defence name — TNO researchers Edwin Stam and José van Uden have already spent the whole morning making little snacks dubbed Nutri-Bites with the help of the 3D food printer. We are given single-use lab coats, hairnets and overshoes and once we have donned these and disinfected our hands, we are allowed in.

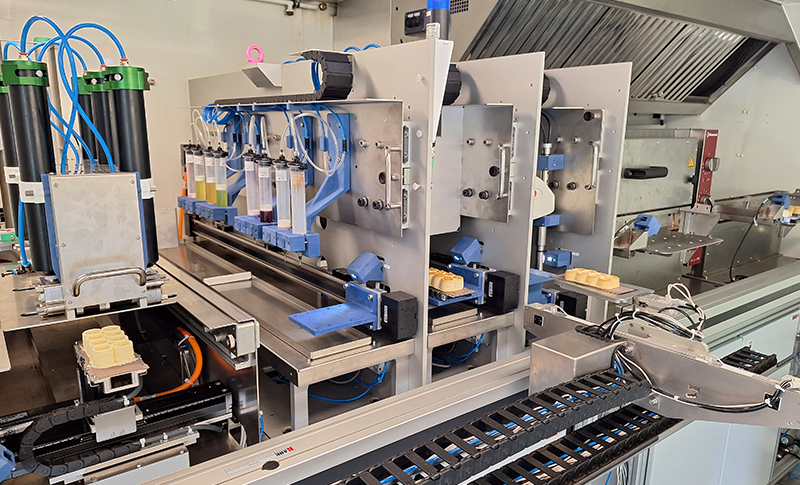

The 3D food printer in the container, or at any rate the constantly moving gripper arm, has been affectionately named Jack by the researchers. The gripper arm delivers little dishes to the machine’s various production stations. The Nutri-Bites are made up of four personalizeable components: the ‘dough’ with which the cups are made, the micronutrient powder that goes on the base of each little cup, a filling and a topping. The result is a snack that looks like something made of puff pastry but has a texture more like shortbread filled with a soft, sweet filling with the consistency of apple sauce or a thick milkshake.

Noort: ‘The 3D food printer works with personal data we feed into it. The snack is adapted to traits of the soldiers such as height, weight and body type, as well as any gastro-intestinal issues and the amount of physical exertion expected of them. So the composition of the snacks is different for each person and we think this will enable us to improve their health and performance with precision.’

The nutritional values match the personal needs

While Noort is explaining the philosophy behind the personalized nutrition, the gripper continuously moves the little trays between the seven stations the installation is made up of. The first production station makes the cups, the outside layer of the Nutri-Bite. Hanging in this machine are six spouts with different kinds of dough, which print four to six cups onto the tray: more for lads who do harder physical work because they need more energy. A QR code on the side of each tray that is linked to each person’s information tells the machine exactly what to do.

Recipes

Wageningen Food and Biobased Research is taking care of the consumer research and the food-technological design for IMAGINE, designing the composition of the various kinds of doughs, fillings and toppings. ‘Based on our scientific knowledge, we make materials with the desired nutritional value which are feasible for the 3D printer and are tasty,’ says Noort. ‘These recipes may be designed to contain as many healthy fatty acids and proteins as possible, for instance, or perhaps as little sugar as possible. As far as we can, we use healthy ingredients like oat bran, almonds, plums or carrots.

This enables us to improve a person’s health or performance with precision

By constructing the snack out of a range of components, we can create a lot of different combinations. So you’ve got combinations like: almond flour + amino acids +apple + caramel; high-protein flour + caffeine + custard + strawberry; or plum + folic acid + peanut butter + lemon. The macro and the micro ingredients in each end product are completely personalized.’

Jack takes a tray from the dough station and delivers it to the closed oven, and then continues to print dough and fill the cups. A bit later, the door of the oven opens to reveal a set of golden baked cups. Then the pale, unbaked cups are rotated into the oven as the baked ones come out. Jack hurries over to the oven. ‘His most important task in the production process is to move the baked cups as quickly as possible to a station where they can cool down,’ explains TNO engineer Edwin Stam.

Once the cups have cooled down sufficiently, they can be filled. Jack takes the tray to the station with the micronutrients, where there are seven pipes full of powder containing the amino acid leucine, caffeine, vitamin C and zinc, among other things. The machine drops a bit of powder into each cup. Now the filling can be added – again, with a number of nutritional variants matching the personal needs of the person who will eat the snack. Flavours include peanut butter, custard, yoghurt and chocolate ganache. At the last stage, each cup gets a topping. ‘That is mainly in order to give the consumer an element of choice,’ says Noort. ‘All the toppings have the same nutritional value, but vary in colour and flavour, because some people prefer strawberry and others caramel.’

There is a plum + folic acid + peanut butter + lemon snack, for example

IMAGINE’s food printer is being tested in two field labs. In Eindhoven, the test is focused on improving the performance of soldiers. Later this summer, a health-oriented test will be done with patients in the Gelderse Vallei hospital in Ede. Noort: ‘We are demonstrating what we can now do and showing that this digital food production technology concept works, and we are researching which aspects need improving.’ By now, Jack has put the toppings on the cups and this is the first point at which a human being is needed: project leader José van Uden picks up the tray and puts it in a box to hand out this afternoon.

Soldiers

And off we go to deliver the snacks to the soldiers. The little boxes are transported to the Weerterheide military training ground, about 20 minutes’ drive from Eindhoven, in a khaki cool box in the boot of a Ministry of Defence 4×4. After a bumpy ride along muddy dirt roads, the all-terrain vehicle comes to a halt in the middle of the woods.

It is quite tasty actually

Camouflaged soldiers emerge from the woods on all sides. They are in training for the infantry, explains Mark Tamis, a Defence logistics staff member. They are spending a couple of weeks in the woods as part of their training. ‘This is a tiring time for them. They are physically on the go all day and often at night too, while they don’t sleep or eat much.’

The soldiers undo their helmets, park their bags on the edge of the path and place their weapons carefully with the barrels facing the woods. One by one, they walk over to the car to pick up their boxes. ‘Oh, I’ve only got six cups again,’ says one of them disappointedly, looking in the box of his mate who gets eight cups. The lads throw themselves down onto the grass besides the path, eat their Nutri-Bites and fill in a questionnaire.

The questions ask about the appearance, mouth-feel and texture of the snacks. No one can compare the Nutri-Bite with anything they’ve ever eaten before. ‘No, I really haven’t ever eaten anything like it. But it’s quite tasty actually. Not the peanut butter flavour though – I hope I don’t get that again tomorrow.’

Once the soldiers have finished their snacks, they return their boxes and fill in a few more answers. One of the questions is: How well did you sleep last night? ‘Er,’ says one of the lads, ‘did I sleep last night? Yes, for half an hour, I think.’ And off they go, back into the woods. Tonight, a computer will process the information just collected and figure out what the snacks for tomorrow should be made of.

This study is supported by the public-private partnership IMAGINE and co-financed by the Dutch ministry of Economic Affairs through the Life Sciences & Health Top Sector (WUR and TNO) and the High Tech Systems and Materials Top Sector (TNO). The private partners involved are the GEA Group, SoliPharma BV, Tate & Lyle, Nissin, General Mills, the Gelderse Vallei hospital and the Dutch ministry of Defence.

The 3D food printer is made up of several stations. The black cartridges on the left contain dough. The toppings come out of the transparent tubes next to them.

Photo Martijn Noort

The 3D food printer is made up of several stations. The black cartridges on the left contain dough. The toppings come out of the transparent tubes next to them.

Photo Martijn Noort